Description

HNC602T is our latest developed, affordable system for cnc lathe & grinding machines. The control circuit adopted with high speed ARM processor ( new industrial grade), large scale filed programmable gate array (FPGA )technology, multi-layer PCB print

Overview:

HNC602T is our latest developed, affordable system for cnc lathe & grinding machines. The control circuit adopted with high speed ARM processor ( new industrial grade), large scale filed programmable gate array (FPGA )technology, multi-layer PCB printed circuit board. The system itself has equipped with high integrated chips and surface mounting components, which brings a more compact and reasonable structure,a better guarantee of the system reliability and stability.

Key features: high speed real-time control(the max fast moving speed can reach to 30m/min, the max feed interpolation speed can up to 15m/min);high precision;using 800*600 lattice TFT LCD brightness adaptive technology ensured a longer service time, eliminated the disadvantage of display brightness varies with ambient temperature.English display menu,operations are very straightforward and convenient.

This is a two-coordinate linkage, open loop cnc system, representing very common application for cnc lathe.It has powerful functions, rich commands, being able to control the AC servo system directly.The programming codes are in accordance with ISO international standard. Choosing the relevant series of servo system from HNC Electric will guarantee you a better cost effective solution.

Features:

1. Coordinate axes: 2

2. Adopting high-speed ARM / DSP / FPGA / hardware interpolation technology

3. Max speed: 60m/min, Feed speed: 0.01…30m/min

4. USB interface

5. RS232 interface

6. Memory for part program: 32M, No limit of the program number

7. Program pre-load for small line segment machining, ensure the continuous machining

8. Max Thread pitch: 1000mm

9. 54 series of G code, satisfy all kinds of machining

10. Automated Tool compensation, C tool compensation function

11. Automated chamfering and rounding function

12. Two-channel anolog output, allow to control two spindle

Parameters:

System constructions

1. 32-bit high performance, low power consumption industrial grade ARM microprocessor.

2. 64MB memory.

3. 32Mb user store room.

4. 8 inch real color LCD display with 640×480 resolution

5. High anti-jamming switch power.

6. USB port

7. RS232 port

8. Spindle servo speed control/spindle frequency conversion speed control.

9. Manual pulse generator.

System technical parameter

1. Controllable axes:X、Z

2. linkage axes:Arc 2 axes, liner 2 axes.

3. Pulse equivalent:X、Z:0.001mm.

4. Max speed:X、Z:60000mm/min.

5. Cutting speed:1-10000mm/min.

6. Min input unit:0.001mm.

7. program size range:± 99999.999.

8. 99 tools management

9. Controllable liner vertical type or revolving disc type tool changer

10. Program code:ISO-840 international standard

11. Program coordinate system definition:ISO-841

12. Chassis protection complies with regulation of IP43

System function

·Auto-diagnosis function

All related diagnosis of CPU, memory, LCD, I/O interface, parameter status, coordinates, machining program etc. shall execute when the system starts or resets. In operation, it makes real time diagnosis of power, spindle, limit and all I/O interface.

·Compensation function

Automatic backlash compensation

Tool radius automatic compensation

Tool radius automatic offset and sharp angle transition

Leading screw pitch error automatic compensation

·Abundant instruction system

Scaling up/down instruction

Mirror machining instruction.

Multiple tool offset instruction.

Program cycle, jump, call and different program ending

multiple positioning instruction:starting point,setting fixed point, etc.

Linear, circular, spiral line interpolation instruction.

Program management instructions: program cycle, call, transfer and different program ending method, etc.

6 work-pieces coordinate system

·Chinese/English menu, full screen edition

Easy operation, convenient viewing

·Abundant debugging functions

it can point out clearly what errors of operation are and guide to correct them.

·Program changing between CNC system and IBM/PC series compatible computer

It can conduct CAD/CAM/CAPP auxiliary programming by using Pc series compatible computer’s abundant software resources,then transfer the CNC program into the system to machining through(USB movable U disc copy port、RS232 port).Likewise it also can transfer the program from system to PC through communication port.

pindle

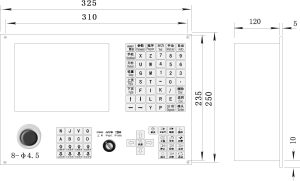

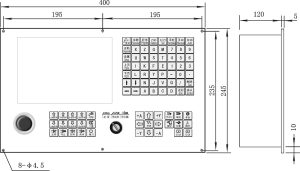

Dimension:

Download:

| Series | Model | Download |

| CNC Controller | 602T Uers Manual | |

| CNC Controller | 602T Brochure |