Description

Aiming at the global high-grade CNC control system, the company developed HNC-848 high-grade all-digital bustype system.

Overview:

Stylish, reliable performance

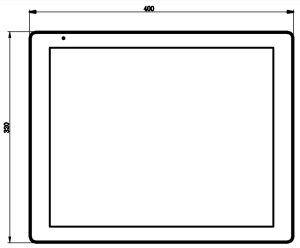

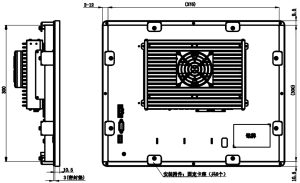

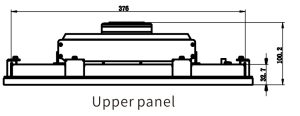

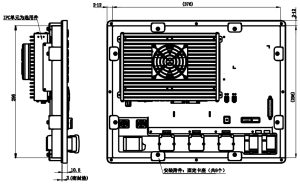

HNC-848 adopts the modular, open architecture, NC and MPC structure of dual CPU module and17” LEDLCD.

Interface template switching function

The use of HNC-848 scripting technology allows HNC8 to have many functions that the traditional CNC system does not have,including skin replacement and multi-language. In consideration the user’s habits, HNC8 HMI system provides a variety of interface templates, users can click to the familiar interface style, reducing the learning curve.

Usability integration technology

The traditional numerical control system is control-based, and HNC-848 is mainly for management. From control to management, the system integration reaches a new height. HMI can integrate local scripts, local dynamic libraries, native applications, and cloud applications with a variety of integration methods and less difficulties.

Highly open

The openness of CNC system is mainly reflected in four aspects: hardware openness, kernel openness, functional openness, and ecological openness. The openness of HNC-848 system hardware is reflected in hardware replaceability; the openness of kernel is reflected in the integration of IEC61131PLC editing tool; the functional openness is reflected in HMl, users can develop custom function modules; the ecological openness is reflected in cloud services. The CNC system can make full use of cloud resources.

Features:

1. High-speed high-precision control

2. 5 simultaneously controlled axes, 5-axis auto calibration, 5-axis RTCP function, Large circular interpolation, Hyperbolic interpolation, 5-axis orientation machining

3. Synchronization control

4. Error compensation

5. Direct drive

6. Intelligent control

7. Lathe-mill combination

8. Multi-channel control

9. Seamless integration of CAM software

10. Touch screen

11. Backlash elimination for multiple motors

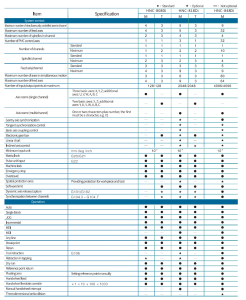

Parameters:

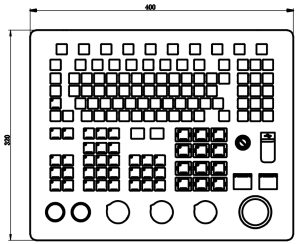

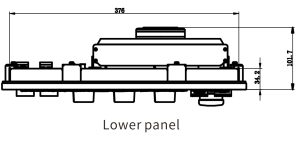

Dimension:

Download: